Capacitors are electronic components that store electrical energy in an electric field. They are widely used in a variety of electronic devices and circuits, such as power supplies, audio equipment, and motor drives.

The basic principle of a capacitor is the ability to store charge on two conducting plates separated by an insulating material, known as the dielectric. The amount of electrical energy that a capacitor can store is determined by the capacitance, which is measured in units of farads (F).

Types of Capacitors

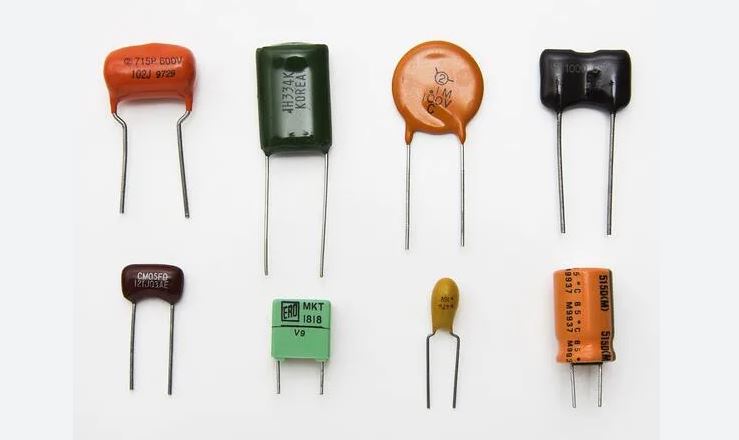

Capacitors are available in a wide variety of types, each with unique characteristics and applications. Some of the most popular types of capacitors include dielectric, ceramic, tantalum, aluminum electrolytic, and film capacitors.

Dielectric Capacitors

Dielectric capacitors, also known as ceramic capacitors, are a type of capacitor that uses a ceramic material as the dielectric. The ceramic material used in dielectric capacitors is made from a mixture of ceramic powder and a binder, which is then shaped and fired at high temperatures.

The ceramic material provides a high dielectric constant, which allows for a large amount of electrical energy to be stored in a small package.

One of the main advantages of dielectric capacitors is their high stability and low leakage current. This makes them well suited for use in circuits where a stable voltage is required, such as in power supplies and timing circuits. They also have a relatively low cost and are widely available in a variety of values and package sizes.

Dielectric capacitors are available in two main types: monolithic and multi-layer.

Monolithic dielectric capacitors are made from a single piece of ceramic material, while multi-layer dielectric capacitors are made by stacking multiple ceramic layers and alternating them with metal electrodes.

In addition to their use in electronic circuits, dielectric capacitors are also used in other applications such as RF (Radio Frequency) and microwave filters, coupling and decoupling, and as energy storage devices. They can also be found in a variety of household devices such as televisions, computers, and radios.

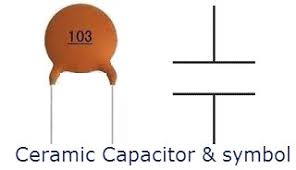

Ceramic Capacitors

Ceramic capacitors are a type of capacitor that uses a ceramic material as the dielectric. They are commonly used in a wide range of electronic applications due to their small size, low cost, and reliable performance. Ceramic capacitors can be found in everything from consumer electronics to industrial equipment, and are widely used in circuits requiring high stability, high precision, and high frequency.

Ceramic capacitors come in many different forms, including disc, chip, and tubular.

- Disc ceramic capacitors are the most common type, and are typically used in general-purpose applications such as coupling, decoupling, and bypassing.

- Chip ceramic capacitors are designed for surface-mount applications and are smaller in size than disc ceramic capacitors. They are widely used in portable devices, smartphones and other electronic devices.

- Tubular ceramic capacitors are large and cylindrical in shape, and are typically used in high-voltage applications such as power supplies.

Overall ceramic capacitors are reliable, cost-effective and widely used in a variety of electronic applications, due to its high stability, high precision, and high frequency characteristics.

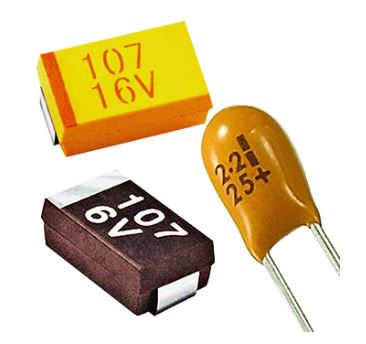

Tantalum Capacitors

Tantalum capacitors are a type of electrolytic capacitor that are widely used in a variety of electronic applications due to their high stability, reliability, and long life. They are made of a tantalum metal electrode that is covered by a thin oxide layer, which acts as the dielectric. The oxide layer is formed by anodic oxidation of the tantalum electrode, and the thickness of the oxide layer determines the capacitance of the capacitor.

Tantalum capacitors offer several advantages over other types of capacitors, such as ceramic and aluminum electrolytic capacitors.

- They have a much higher volumetric efficiency, which means that they can store more energy per unit volume.

- They also have a very low leakage current, which makes them suitable for use in circuits that require long-term stability.

- They have a wide range of capacitance values, which makes them versatile for use in a wide range of applications, such as power supplies, audio equipment, and medical devices.

- They are available in various package types and dimensions, offering a wide range of options for designers.

Due to their high stability, reliability and long life, tantalum capacitors are widely used in critical applications where high performance and long service life are required.

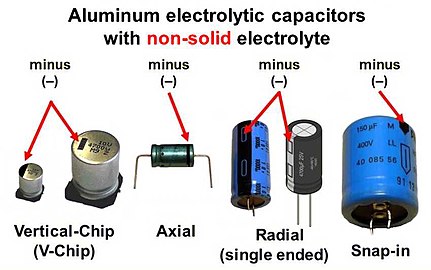

Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are a type of capacitor that uses an electrolyte solution to increase the capacitance of the device. These capacitors are characterized by their large capacitance values, typically in the range of microfarads (µF) to thousands of microfarads. They are constructed with a cylindrical or rectangular aluminum casing that serves as the anode, and a thin layer of aluminum oxide that acts as the dielectric. The cathode is typically a wet electrolyte, usually composed of a mixture of water and boric acid.

One of the main advantages of aluminum electrolytic capacitors is their high energy density, which allows them to store a large amount of energy in a relatively small package. They are also relatively inexpensive, making them ideal for use in a wide range of electronic devices, such as power supplies, audio equipment, and motor drives.

However, they also have some drawbacks, such as a relatively short lifespan, due to the limited lifetime of the electrolyte, and they are also quite sensitive to temperature and voltage changes.

Despite these drawbacks, aluminum electrolytic capacitors remain a popular choice for many electronic applications due to their high capacitance and relatively low cost.

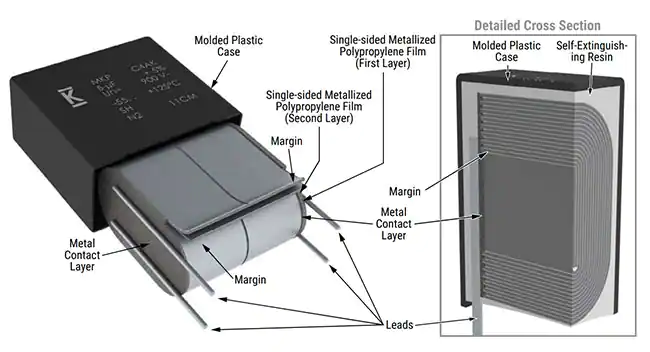

Film Capacitors

Film capacitors, also known as plastic film capacitors, are a type of capacitor that uses a thin plastic film as the dielectric material. They are commonly used in a wide range of electronic applications, such as power electronics, audio equipment, and motor drives.

One of the main advantages of film capacitors is their stability and reliability over a wide range of temperatures and frequencies. They also have a relatively low dielectric absorption and a low equivalent series resistance (ESR), which makes them suitable for use in high-frequency circuits.

Film capacitors can be further divided into several types, such as polyester film capacitors, polypropylene film capacitors, and polycarbonate film capacitors. Each of these types has its own unique characteristics and is used in different applications.

For example:

polyester film capacitors are commonly used in general-purpose applications and are known for their low cost and high stability.

On the other hand, polypropylene film capacitors are used in audio equipment and high-frequency applications due to their high stability and low dielectric loss.

Film capacitors are also available in different voltage ratings and capacitance values, making them suitable for a wide range of electronic applications.

What are they made of?

Capacitors are made up of several different materials, each of which plays an important role in the functioning of the capacitor. The following are the main components of a capacitor and their function:

- Conducting Plates:

The conducting plates are the main component of a capacitor. They are typically made of metal, such as aluminum or tantalum, and are used to store the electrical charge. The size and shape of the plates will affect the capacitance of the capacitor. The larger the plates and the closer they are to each other, the greater the capacitance.

- Dielectric Material:

The dielectric material is the insulating material that separates the two conducting plates. It is used to increase the capacitance of the capacitor by reducing the distance between the plates. The most common dielectric materials used in capacitors are ceramic, paper, and plastic. Ceramic capacitors are known for their high stability and temperature coefficient, while paper and plastic capacitors are known for their low cost and ease of manufacturing.

- Electrolyte:

Electrolytes are liquid or gel-like substance that is used in some types of capacitors, such as electrolytic capacitors. It serves as the conductive medium between the anode and cathode terminals in the capacitor. The most common electrolyte used in capacitors is a mixture of water and sulfuric acid.

- Terminals:

The terminals are the leads that are attached to the capacitor. They are used to connect the capacitor to the circuit. The terminals are usually made of metal, such as copper or aluminum, and are attached to the conducting plates.

Testing

There are several methods for testing capacitors, including visual inspection, resistance measurement, and capacitance measurement.

Visual inspection is a quick and easy way to check for obvious signs of damage, such as bulging or leaking.

Resistance measurement, also known as a continuity test, can be used to check for an open or shorted capacitor.

Capacitance measurement, which is the most accurate way to test a capacitor, can be done using a capacitance meter or multimeter with a capacitance function. Capacitance measurement will indicate whether the capacitor is functioning within its specified tolerance range.

When testing capacitors, it is important to note that capacitors should not be tested under load, as this can cause damage to the component.

Before testing, the device or circuit that the capacitor is in should be disconnected from power.

To learn more check this article out: How to Test a Capacitor 3 Different Ways

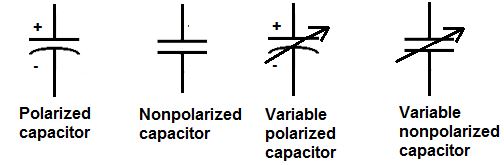

Capacitor Symbols

It is important to be familiar with electrical schematic symbols in order to properly read and interpret capacitors in circuit diagrams.

Note: The value of the capacitor is sometimes marked next to the symbol, indicating the capacitance in Farads.

PDFs / Technicals

Useful Resources

Centrifugal Switch: What They Do, How They Work and When To Use Them

Choose The Right Motor Starter – Types and How They Work

Dimmer Switches: Wiring, Diagrams and Installation Suggestions

Phase Monitoring Relays: How They Work